Intelligent equipment

Custom Pipe Package Custom Pipe Package ABB body cable Customized communication cable Custom Robot Power Cable Custom KUKA Cable Custom FANUC Cable ABB Teach Pendant Cable

Name: Front Subframe Assembly Line for Automotive Chassis Process: The production line uses manual feeding, automatically completes the pressing of seven bushings and automatic rivet bolts, and automatically completes laser marking. It is eq

Process: End face runout detection, automatic steering knuckle bolt tightening, brake caliper and oil pipe bolt tightening, ABS wiring harness detection, front strut assembly, trailing arm assembly and half-shaft assembly, traceability syste

Process: Automatic upper and lower bushing pressing, automatic screw tightening, manual labeling of finished products, traceability system, automatic storage of pressing curves and tightening parameters. Features: Meets the production needs

Process: AGV loading of axles and kits, press-fitting of PSIs, bushings, camshafts and accessories, brake shoes, wheel hubs, bearing lubrication and loading, press-fitting of oil seals, tightening of shaft end nuts, brake calipers and air ch

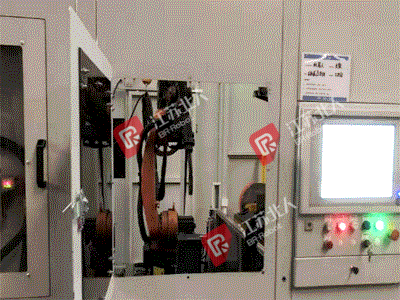

Process Equipment: CNC drilling machines, machining centers, high-pressure cleaners, honing machines, and measuring machines, etc. Processes: Machining, O-ring assembly, press-fitting of plugs, automatic plug tightening, etc. Features: Robot

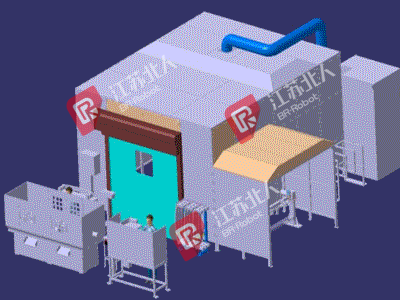

Glue Coating and Curing Sealing strips, glue coating and curing equipment, improve the cycle time of glue coating and curing through temperature control, thereby improving the automation efficiency of the production line. Laser Welding It ha

Designed Production Capacity: 15 Main Process Types: Glue application, drying and curing, airtightness testing, etc.

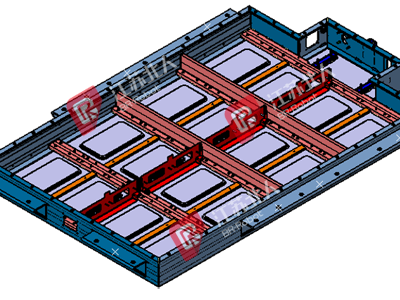

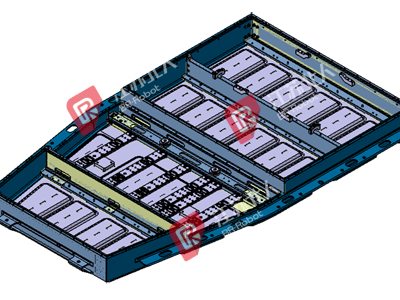

Designed Output: 4 Flexible Switchover Production with MCE Main Process Types: Riveting, Arc Welding, Friction Stir Welding, Machining, Drilling Tapping, Cleaning, etc.

Designed Production Capacity: 8 Main Process Types: Arc welding, friction stir welding, machining, drilling and tapping, cleaning, gluing, assembly, etc.

Designed Output: 8 Main Process Types: Arc welding, friction stir welding, machining, drilling and tapping, cleaning, gluing, assembly, etc.

Year: 2018 Product: Rear floor of a certain car model Cycle time: 10 JPH Process: Spot welding, glue application, stud welding Robots: 12 units Features: Flexible production line 1. Three car models are produced on the same line (one model i

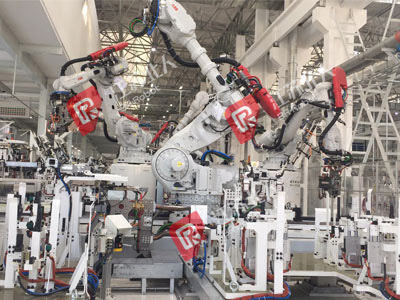

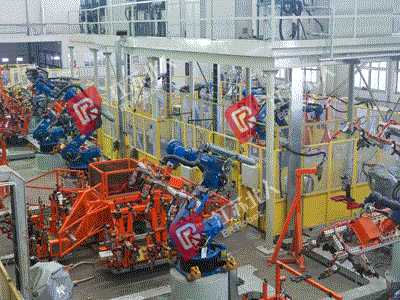

Part Name: Automated Production Line for Front Longitudinal Beam of a Certain Model Number of Robots: 12 Production Capacity: 30 JPH Processes: Robot spot welding, robot handling, robot stud welding Features: Fully automated production line;

Part Name: Automated Production Line for Rear Wheel Cover of a Certain Model Number of Robots: 7 Daily Production Capacity: 400 sets Process: Fully automated production line with robotic spot welding, robotic handling, robotic gluing, and ro

Part Name: Automated Production Line for Rear Side Panel of a Certain Car Model Number of Robots: 12 Daily Production Capacity: Approximately 600 sets Processes: Robot spot welding, robot handling, robot stud welding Features: The product is

Part Name: Automated Production Line for Front Upper and Lower Panels of a Certain Car Model Number of Robots: 30 Daily Production Capacity: Approximately 800 sets Processes: Robot spot welding, robot handling, robot gluing, robot stud weldi

Year: 2015 Product: Sunroof riveting for a certain car model Cycle time: 30 JPH Process: Spot welding, projection welding, TOX riveting Robots: 2 units Features: Wide range of processes applied, incorporating all sunroof screw connections, n

Year: 2017 Product: Front floor of a certain car model Cycle time: 55 JPH (65s) Process: Spot welding, glue application, stud welding, arc welding Robots: 28 units Features: Wide range of process applications, high system integration, flexib

Part Name: Automated Production Line for Four-Door Hemming of a Certain Car Model Daily Production Capacity: Approximately 800 sets Processes: Robotic spot welding, robotic handling, robotic hemming Features: Fully automated production line;

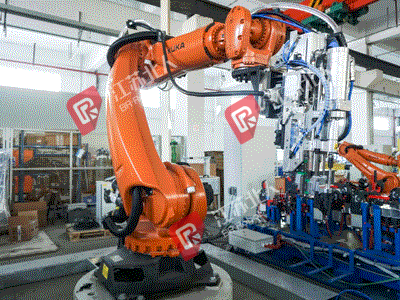

Part Name: Arc Welding Station for a Certain Model Bumper Number of Robots: 2 Daily Production Capacity: Approximately 800 sets Process: Robotic Aluminum Alloy Arc Welding Features: Employs a three-axis positioner; the welding chamber is sea

400-1016-959

400-1016-959 Map

Map