Battery tray business

Process Introduction

Release time:2025-12-12 |Author:admin |Reading:2481Times

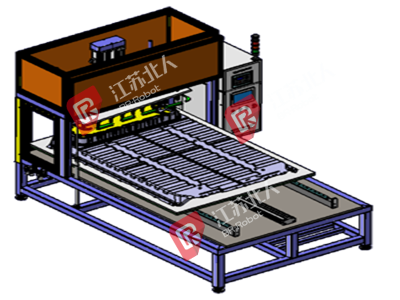

Glue Coating and Curing

Sealing strips, glue coating and curing equipment, improve the cycle time of glue coating and curing through temperature control, thereby improving the automation efficiency of the production line.

Laser Welding

It has multiple process capabilities such as laser flying welding, laser penetration welding, laser brazing, and laser filler wire welding, to meet the diverse needs of customers for different applications

Glue Coating Inspection

Fully Automatic Vision Glue Coating Quality Inspection

/>

/>

Air tightness test

Gas at a certain pressure is introduced into the workpiece cavity, and the leakage status of the battery box cavity is measured by a specialized instrument, and the leakage rate is given.

Cleaning

Automatic cleaning removes oil and welding dust from parts.

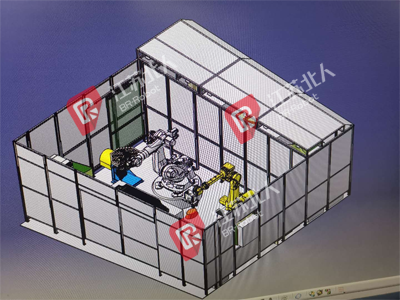

Riveting

A robot grips the parts to a fixed riveting station; the equipment automatically feeds the rivets and completes the riveting operation.

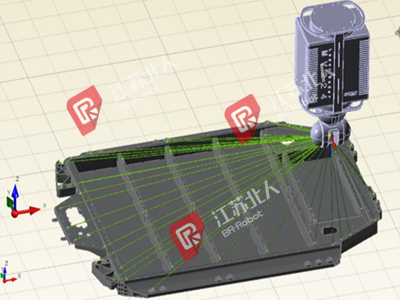

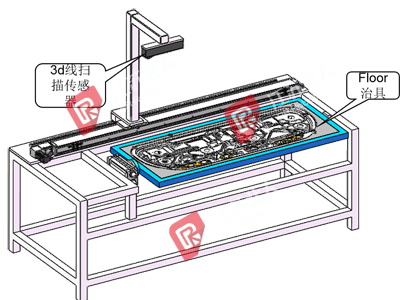

Online Laser Radar Detection System

1. Non-contact optical measurement: single feature measurement + scanning

2. Simulated three-coordinate sampling method: high accuracy and high efficiency of feature measurement

3. Accuracy: 0.053mm within 5M range, 0.024mm within 2M range

4. High repeatability accuracy: 0.03mm for points, 0.05mm for holes; full station coverage, 100% measurement reachability

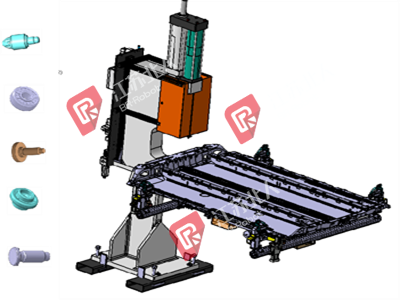

Nut Leakage Prevention Detection

Automatic error prevention and leakage detection of parts through a visual 3D point cloud system

上一篇:A battery box adhesive coating production line

下一篇:暂无

400-1016-959

400-1016-959 Map

Map