Bodywork business

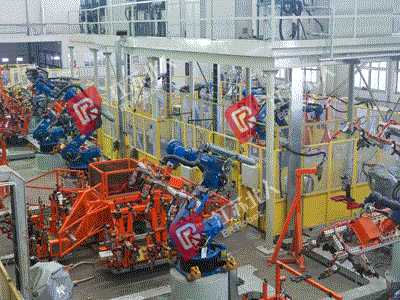

Jiangsu Beiren's bodywork business has always focused on automotive parts and original equipment manufacturers (OEMs) as its main customers, striving to provide flexible, automated, and intelligent production lines and related services.

The company has completed the design, manufacturing, and system integration of fixtures for production lines covering a wide range of body parts, including front and rear longitudinal beams, front and rear floor panels, seat frames, front and rear side panels, upper and lower front panels, tail panels, radiator crossbeams, bumpers, and four doors.

Through over ten years of effort and the successful delivery of thousands of projects, Jiangsu Beiren has accumulated rich experience in production line integration for welding applications. It has achieved flexible functions such as standardized product switching, standardized positioners, and standardized fixtures. The company has mastered a series of body connection processes, including spot welding, arc welding, laser welding, hemming, adhesive application, stud welding, rotary tapping and riveting, self-piercing riveting, press riveting, pull riveting, and projection welding. It also applies core intelligent technologies such as offline programming, virtual commissioning, remote operation and maintenance, vision guidance, online measurement, and MES systems to relevant projects, aiming to provide customers with professional, customized, and lean industry solutions.

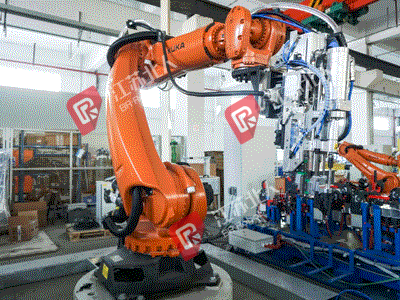

Part Name: Automated Production Line for Rear Side Panel of a Certain Car Model Number of Robots: 12 Daily Production Capacity: Approximately 600 sets Processes: Robot spot welding, robot handling, robot stud welding Features: The product is

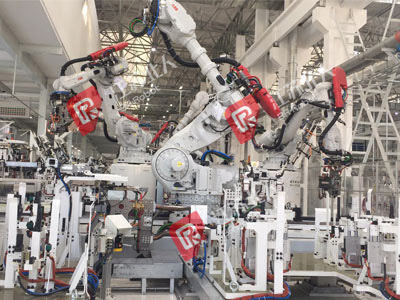

Part Name: Automated Production Line for Front Upper and Lower Panels of a Certain Car Model Number of Robots: 30 Daily Production Capacity: Approximately 800 sets Processes: Robot spot welding, robot handling, robot gluing, robot stud weldi

Year: 2015 Product: Sunroof riveting for a certain car model Cycle time: 30 JPH Process: Spot welding, projection welding, TOX riveting Robots: 2 units Features: Wide range of processes applied, incorporating all sunroof screw connections, n

Year: 2017 Product: Front floor of a certain car model Cycle time: 55 JPH (65s) Process: Spot welding, glue application, stud welding, arc welding Robots: 28 units Features: Wide range of process applications, high system integration, flexib

Part Name: Automated Production Line for Four-Door Hemming of a Certain Car Model Daily Production Capacity: Approximately 800 sets Processes: Robotic spot welding, robotic handling, robotic hemming Features: Fully automated production line;

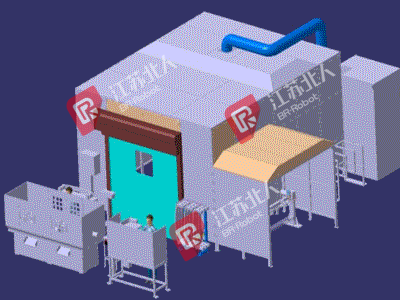

Part Name: Arc Welding Station for a Certain Model Bumper Number of Robots: 2 Daily Production Capacity: Approximately 800 sets Process: Robotic Aluminum Alloy Arc Welding Features: Employs a three-axis positioner; the welding chamber is sea

400-1016-959

400-1016-959 Map

Map